Why do you need a Digital Twin?

Why you need a Digital Twin

As the economy slowly begins to reopen, the buzzword "Digital Twin" is gaining popularity as a must-have in the world of manufacturing and construction. Companies are keen to store digital data they can work with remotely in the event of a breakdown or pandemic, and they're also looking for ways to boost productivity and cope with the recession. That's why hundreds of service providers are striving to deliver these sought-after tools to businesses worldwide. But what exactly is a "Digital Twin", and why do you need one?

What is a Digital Twin?

'' 5 things you should be able to do with your 3D model

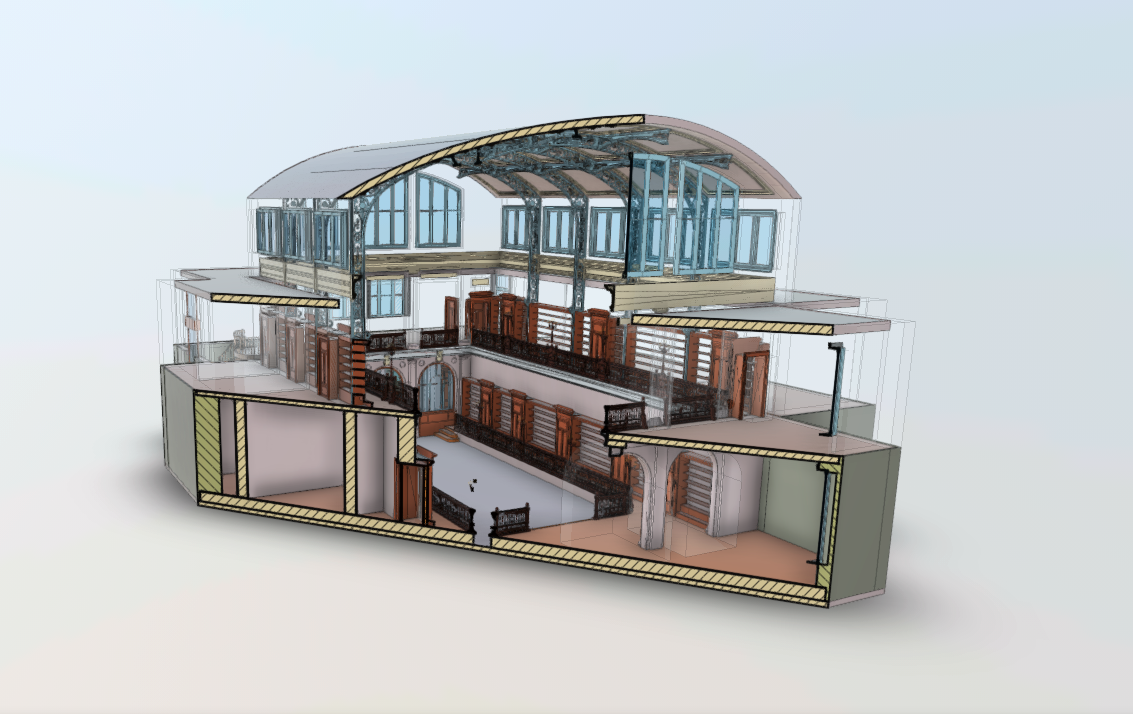

A digital twin is a virtual representation of a real-world product or asset. It can be a digital representation of a physical asset, a workflow, a process, or all of the above. While the concept of the digital twin has been around for some time, the true digital twins we see today are quite new. That's because the tools we use to create them have only recently been developed. The emergence of more accessible precision instruments, such as 3D laser scanners like the Leica RTC360, improved modeling software (like Matterport or Autodesk BIM) and better information all contribute to the quality of a modern digital twin. Today, hundreds of companies use this tool every day to improve their operations.

What can a digital twin be used for?

'' How modern point cloud management can help you through the crisis.

You can use a digital twin for almost anything. From virtual staging to simulating a rocket launch, a data-accurate digital twin can simulate almost any form of experience in digital space, provided the right tools compile the result. One of the most common uses for a digital twin is to help architects coordinate with civil engineers. As they tend to work with physical structures, the replication process is fairly well known and documented. The structure is scanned in 3D or drawn by hand, then modeled according to needs or objectives. Once the modeling is complete, an architect and civil engineer can coordinate, collaborate and define the necessary steps prior to operations. This process saves time and money, and improves communication between the different teams.

How to make a digital twin?

'' The advantages of 3D laser scanning technology

'' The value of the automated point cloud for the mesh

In today's world, creating the perfect digital twin requires precision instruments like the Leica BLK-360 or RTC360, or other 3D laser scanning technologies. Once the information has been captured, you can take a number of different routes. On the one hand, you can create a model using one of the software solutions available (Matterport, BIM Revit or other). With this method, the modeling process is highly dependent on the quality of the scan, and the modeling itself can take quite a long time, depending on the complexity of the project. This is why BIM coordination tools have also appeared on the market. Another method is to use scan-to-mesh tools, which are innovative and faster. The only problem with scan-to-mesh is that there are not yet many choices available on the market. Whatever the method, digital twins are gaining in popularity as an indispensable tool for many users and service providers.

How can a digital twin help your workplace?

'' How 3D scanning can help your business

'' Improve your technical communication with an interactive 3D model

Due to the economic disruption of the pandemic, the need to reorganize or optimize the workplace is becoming increasingly important. For example, it is becoming increasingly important to reorganize production lines in response to financial instability. Digital twins can help you reduce the productivity of your production line. It all starts with a simple analysis and compilation of a data set. Once the data set has been refined, the digital twinning process can begin. The digital twin represents reality and can simulate a workplace change so that you can validate it before the actual event. This enables the team to plan, coordinate and optimize their workflow, and improve their return on investment.

What challenges can digital twins solve?

'' Advantages and disadvantages of visualization and modeling software

Digital twins solve inefficiencies. Their raison d'être is to simulate events before carrying them out, thereby minimizing risk and avoiding errors. By centralizing a simulation, stakeholders can make more important decisions with less investment. As the world restarts its economy and people return to work, simulations, real-life testing and constant benchmarking will be the ultimate differentiators to keep your organization up and running. It all starts with analysis and your own digital twin.

Contact GoVR to get yours today.